Direct-to-Film (DTF) transfers have reshaped the custom apparel industry with their vibrant colors, durability, and adaptability across many fabrics. Yet, when it comes to determining the right size for your DTF transfers, many customers face a common challenge. It’s not simply a matter of “bigger is better.” Transfer size impacts the garment’s overall look, feel, comfort, and longevity.

At CapitalAreaSign.com, our extensive experience serving a wide spectrum of clients—from local businesses and sports teams to startups and individuals—has taught us that selecting the ideal dimensions is both an art and a science. In this comprehensive guide, I will walk you through everything you need to know about choosing the perfect size for your DTF transfers. We’ll cover common use cases, fabric considerations, technical limitations, design complexity, case studies, and much more to ensure your next project is a resounding success.

Understanding the Importance of Transfer Size in Your DTF Project

Before we dive into specifics, it’s important to understand why transfer size matters so much.

- Aesthetic Balance: The size of the transfer must complement the garment without overwhelming or underwhelming it. A transfer that’s too large can look bulky or awkward, while one that’s too small may be illegible or unimpressive.

- Comfort and Wearability: Oversized transfers can stiffen the fabric, reducing comfort and causing the garment to wear out faster. Appropriately sized transfers maintain the softness and flexibility of the clothing.

- Print Quality and Detail: The size of your transfer influences how clearly details and colors appear. Too small a transfer can cause loss of intricate details, while too large a transfer risks ink bleeding or cracking.

- Durability: Larger transfers expose more surface area to stress from washing and daily wear, which can increase the risk of cracking or peeling if not sized and applied correctly.

Common Use Cases and How They Shape Your DTF Transfer Size

Your transfer size will vary depending on the end use of the apparel or merchandise. Let’s explore the most common applications:

Custom Apparel for Businesses and Events

Local businesses, schools, nonprofits, and event organizers often need branded apparel to promote their message. The size of the transfer depends largely on where it will be placed and the desired visibility.

- Chest Logos (3-5 inches): For employee uniforms or event staff shirts, smaller logos positioned on the chest create a professional, clean look without distracting from the garment’s fit or design.

- Full Back Designs (10-12 inches or larger): These are great for making a statement at events or sports games where visibility from afar matters.

- Sleeve or Pocket Transfers (2-4 inches): Smaller accents such as sleeve logos or pocket prints add subtle branding without bulk.

Personalized Gifts and Merchandise

DTF transfers shine in the custom gifts market. From tote bags and hats to hoodies and sweatshirts, medium-sized transfers ranging from 6 to 9 inches are popular because they:

- Fit well on smaller items without overpowering.

- Allow for clear visibility of designs and text.

- Maintain comfort by not adding too much stiffness.

Sports and Team Apparel

For athletic wear, transfer size balances visibility with flexibility.

- Player Numbers and Names (8-12 inches tall): These sizes ensure that numbers are readable from a distance during gameplay.

- Team Logos and Sponsors: Often placed on the chest or sleeves, these are sized between 4 to 7 inches to avoid restricting movement.

Our work with local leagues has shown that adjusting transfer size even slightly can improve athlete comfort and garment durability, encouraging teams to come back season after season.

Small Business and Startup Branding

Startups and small businesses rely on DTF transfers for flexible, affordable runs of branded merchandise. Common sizes here vary widely because:

- Entrepreneurs want some items with small, discreet branding (4-6 inches).

- Others prefer statement pieces like hoodies or bags with larger transfers (8-10 inches).

We advise clients on balancing brand visibility with product comfort to maximize appeal and customer satisfaction.

Fabric Types and Garment Styles: The Unsung Heroes of Transfer Sizing

Many overlook how fabric and garment style dictate what size transfer will work best. At CapitalAreaSign.com, we emphasize tailoring size recommendations based on these crucial factors.

Fabric Types

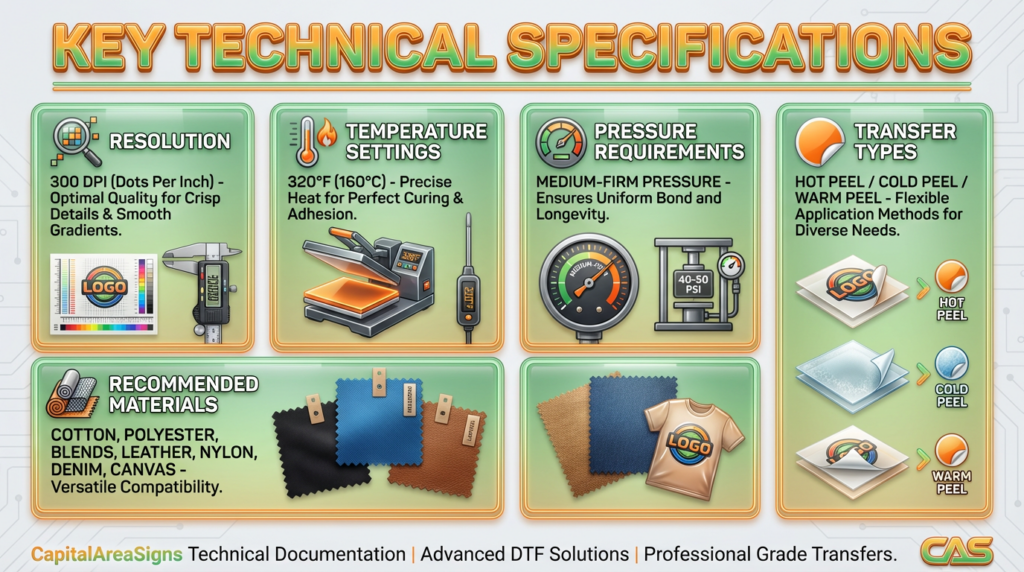

- Cotton and Cotton Blends: These fabrics are ideal for DTF transfers. Their smooth texture and breathability allow larger transfers to sit comfortably on the garment, with less risk of cracking or stiffness.

- Polyester and Performance Fabrics: Common in athletic wear, these fabrics stretch and wick moisture. Large or stiff transfers can crack as the fabric moves, so moderate sizes are preferred to maintain flexibility.

- Delicate Fabrics (Silk, Thin Knits): These require small, lightweight transfers that do not interfere with the delicate weave or drape.

- Denim and Heavyweight Fabrics: These can handle larger, more durable transfers but may require stronger adhesives or heat press settings.

Garment Styles

- Fitted Apparel: Slim or tailored fits work best with smaller, well-placed transfers that enhance the garment’s cut. Large transfers risk making the fabric feel tight and stiff.

- Oversized or Baggy Clothing: The extra surface area can carry larger transfers effectively, allowing for bold, statement-making designs.

- Outerwear and Jackets: Thicker fabrics and seams require strategic placement of medium to large transfers, avoiding bulky seams and ensuring proper adhesion.

Real-World Tip:

When consulting clients, we always request fabric swatches or garment samples when possible. Seeing and feeling the material firsthand lets us recommend transfer sizes that work harmoniously with the fabric’s unique properties.

Case Studies: How Choosing the Right Size Made a Difference

Let’s look at three detailed client stories that highlight the critical role transfer sizing played in their success.

Case Study 1: Community Soccer League

A local league wanted bold player numbers on jerseys. They initially opted for 14-inch tall numbers, which created stiff, uncomfortable jerseys that restricted player movement.

Our Solution: After assessing the issue, we recommended scaling the numbers down to 10 inches. This smaller size struck a perfect balance between visibility and comfort, leading to happier players and repeat orders.

Case Study 2: Boutique Apparel Brand Launch

A startup wanted oversized chest logos on hoodies to establish brand identity. The initial design covered nearly half the front, making the hoodies heavy and inflexible.

Our Solution: We suggested a 7-inch wide logo, maintaining visual impact while improving garment flexibility. Customer reviews praised the fit and feel, helping the brand gain momentum in a competitive market.

Case Study 3: Corporate Event T-Shirts

A major company ordered branded t-shirts with both small chest logos and large back designs. Poor planning initially caused uneven sizing that looked cluttered.

Our Solution: We created mockups demonstrating optimal size ratios, balancing small front logos (around 4 inches) with larger but not overpowering back prints (12 inches). The final product looked polished and professional, resulting in positive feedback and ongoing partnerships.

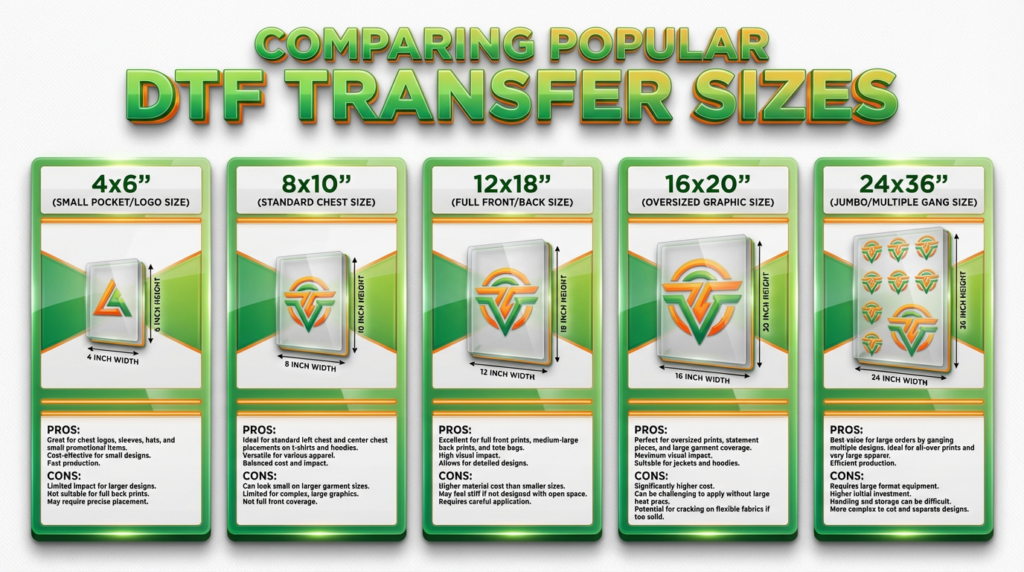

Technical Constraints and How They Influence Transfer Dimensions

While creativity matters, technical realities set boundaries for your transfer size.

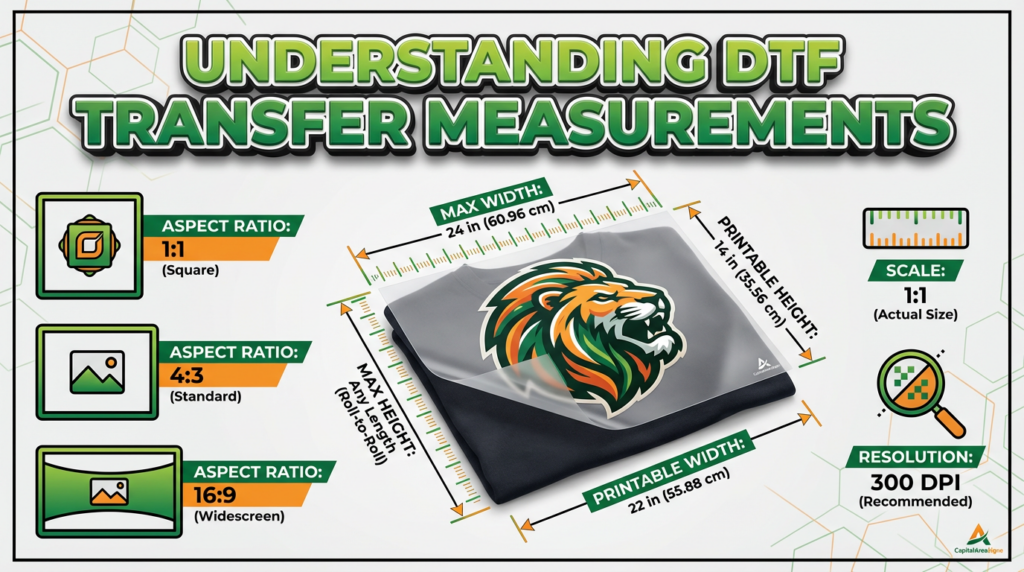

Printer Capabilities

Most commercial DTF printers can print transfers up to about 24 inches wide. Larger sizes require either special equipment or printing in sections, which can complicate production and raise costs.

Artwork Resolution and Detail

For sharp prints, artwork should be at least 300 DPI at the final print size. Scaling up low-resolution images leads to pixelation and blurry designs.

Ink, Film Thickness, and Feel

DTF transfers use multiple layers (color ink, white underbase, adhesive). Larger transfers have more layers, potentially making the print thick and less flexible. This can reduce comfort and increase the risk of cracking.

Heat Press Limitations

The size of your heat press restricts the maximum transfer you can apply in a single press. Transfers larger than the press bed require careful multi-step pressing, increasing the chance of imperfections.

Achieving the Perfect Balance Between Size and Design Detail

For intricate artwork, the right transfer size is crucial to preserve clarity and vibrancy.

- Minimum Size Thresholds: Extremely small transfers may lose fine details and textures, making the print appear muddy or unclear.

- Scaling Proportions: Distorting artwork to fit a specific size leads to stretched or squashed images, damaging design integrity.

- Simplification Strategies: Sometimes breaking a complex design into multiple transfers or simplifying fine details ensures crisp, clean prints.

- Placement Considerations: Small placements like sleeves or pockets require scaled-back detail levels compared to larger placements like backs or fronts.

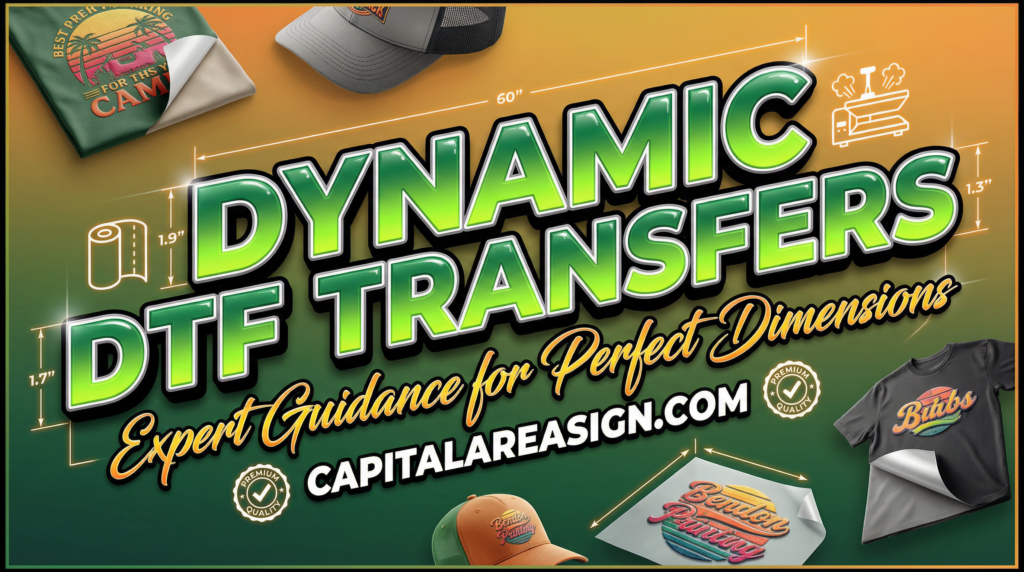

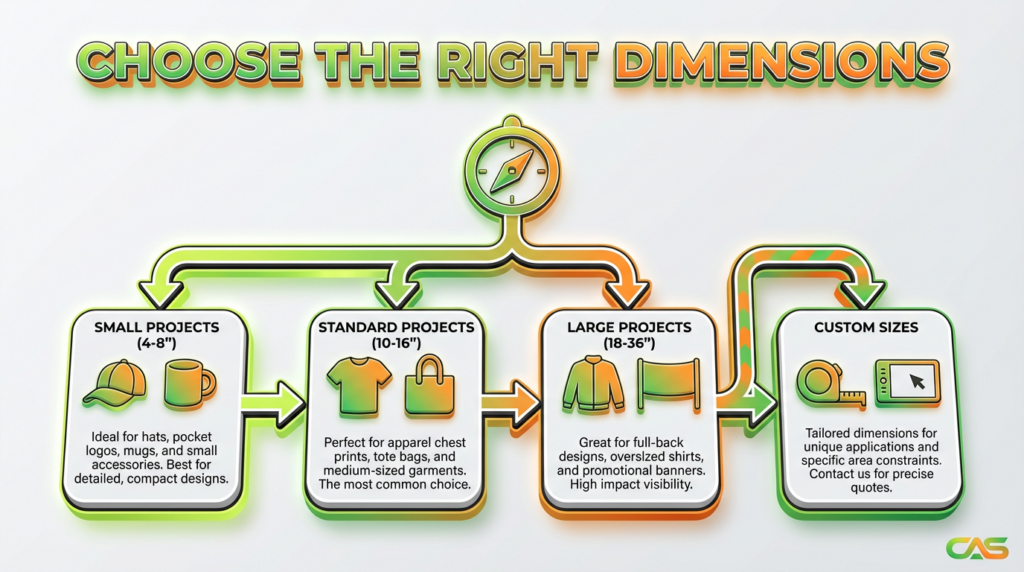

Standard Size Ranges: Tried and True Recommendations

Based on extensive experience and client feedback, here are typical size ranges for popular DTF applications:

| Application | Transfer Width Range |

| T-Shirt Chest Logo | 4 to 8 inches |

| T-Shirt Full Front | 9 to 12 inches |

| T-Shirt Back | 10 to 14 inches |

| Hoodie Chest/Arm | 4 to 7 inches |

| Hoodie Back | 12 to 16 inches |

| Tote Bags & Backpacks | 5 to 12 inches |

We adjust these recommendations based on garment style, fabric, and design complexity for optimal results.

Avoiding Common Sizing Mistakes: Expert Tips

Clients often make avoidable errors such as:

- Oversized Transfers Causing Stiffness: Large transfers on soft garments make fabric rigid and prone to cracking.

- Transfers Too Small for Detailed Designs: Intricate artwork shrinks into illegibility.

- One-Size-Fits-All Mentality: Ignoring differences in fabric and garment cut leads to poor fit and appearance.

- Ignoring Equipment Limits: Oversized designs beyond printer or heat press capabilities cause production delays and poor adhesion.

At CapitalAreaSign.com, our consultation process includes education, mockups, and practical advice to prevent these mistakes.

The Role of Garment Color and Printing Method in Transfer Sizing

Color and printing techniques influence transfer size and feel.

- Light Garments: Often do not require white underbase, resulting in thinner, more flexible transfers. This flexibility allows for slightly larger transfer sizes without compromising comfort.

- Dark Garments: Require a white underbase layer beneath the color to ensure vibrancy, adding bulk. Larger transfers here can feel stiff, so moderate sizing is best.

- Printing Method Impact: Single-layer prints on light fabrics are thinner; multi-layer prints on dark fabrics necessitate careful sizing to balance vibrancy and comfort.

Environmental and Usage Factors Affecting Transfer Size and Placement

Durability is as important as design.

- Washing: Larger transfers face more stress during washing cycles, increasing risk of wear. Choosing appropriate sizes and placements helps transfers last longer.

- Wear and Tear: High-friction areas (underarms, seams) are less suitable for large transfers, which tend to crack faster in these zones.

- Usage Context: Garments used for active or outdoor purposes benefit from strategically sized and placed transfers to balance durability and appearance.

Beginner’s Guide: Selecting Your First DTF Transfer Size

If you’re new to DTF transfers, here’s a straightforward approach to sizing:

- Start with Standard Sizes: 4 to 8-inch chest logos are versatile and low-risk.

- Consider Placement: Smaller for sleeves or pockets; larger for backs or fronts.

- Respect Design Detail: Don’t shrink intricate artwork too much—start slightly larger.

- Match Fabric Type: Soft cotton handles bigger transfers better than delicate materials.

- Seek Professional Guidance: Reach out to experts like CapitalAreaSign.com for tailored advice.

FAQs: Answering Your Transfer Size Questions

Q: What if my artwork is very detailed but I want a small transfer?

A: We recommend simplifying the design or increasing the transfer size to maintain detail clarity.

Q: Can I have transfers on stretchy fabrics?

A: Yes, but size should be moderate to prevent cracking and maintain garment flexibility.

Q: Are bigger transfers always more durable?

A: Not necessarily. Larger transfers face more stress and can be less flexible, potentially cracking over time.

Q: How do I know if my heat press can handle my transfer size?

A: Check your heat press bed dimensions and ensure the transfer fits comfortably for even pressure.

Final Thoughts: Why Transfer Size Matters More Than You Think

Choosing the right dimensions for your DTF transfers is a blend of creative vision, technical understanding, and practical experience. At CapitalAreaSign.com, we bring these elements together to help you create custom apparel and merchandise that not only looks stunning but feels great and lasts long.

Your transfer size affects visibility, comfort, durability, and overall garment appeal. Getting it right means happier customers, better brand representation, and more repeat business.

If you’re uncertain or want personalized recommendations, don’t hesitate to contact us. Together, we’ll find the perfect transfer size tailored to your project’s unique needs.